I’ve been wanting to make a tufted headboard for our master bedroom since before we moved in, and last week Eddie and I finally got around to making it!

Here in part one, I’ll cover everything involved in getting the headboard ready for tufting. I’ll be back with the tufting and finishing process in part 2 next week (update: see part 2 here)!

I looked at dozens of blogs, online tutorials, and videos for hints, tips, and inspiration. My favorite tufted headboard tutorials are from Addicted 2 Decorating, Schue Love, Little Green Notebook, Living with Punks, Brick City Love, Involving the Senses, and Pretty Dubs. I ended up picking and choosing pieces from several of the tutorials, and through that and trial & error we came up with a process that worked pretty well.

Supplies for my queen size headboard

- Pegboard* 60″ by 40″

- 2″ foam – I used one 2′ by 7.5′ piece from JoAnn’s (use a coupon – it’s not cheap!)

- Spray adhesive

- Hi-loft batting in full bed size package

- A small paring knife you don’t mind using on foam. An electric meat carving knife like this one is also nice to have, especially if you’re doing a non-rectangle shape.

- 3 yards of fabric that is at least 54″ wide (I wanted to use skinnier fabric, so I got two 3 yard sections and sewed them together lengthwise)

- sturdy string or twine (I used 4-ply baker’s twine left over from wedding invites)

- a fabric button cover kit and wire eye back blanks. I used 45 3/4″ buttons from here

- heavy-duty staple gun with 1/2″ staples

*A note about using pegboard vs. normal wood, plywood, or mdf: I wanted to use pegboard because there is already a handy grid of evenly spaced holes. However, this does slightly limit your tuft placement possibilities (half of my tufts were directly between two holes to get my spacing how I wanted it – but this wasn’t a huge deal). More importantly, our staple gun at least does not work excellently in the pegboard because it is a higher density. We even got a heavy-duty pro version (this one) which helped, but still about 20% of our staples didn’t work. Plus its a pain to use many times in a row. Some people use staples to attach tufts – which didn’t work for us in the pegboard. Our staple guns both work great in scrap wood though, so something less dense would be better if you want to attach tufts with staples. We still used staples to attach the batting and fabric around the edges – we just pulled out the ones that didn’t work and redid those. I’m still glad we used pegboard this time, but I think if we were doing it again I might use MDF. It would add a huge step in laying out the holes and drilling them in a perfectly spaced layout, but it gives more freedom in button spacing.

First, we cut the pegboard to size for our headboard – you can have them do this for you at the store as long as you know what size you want your headboard to be when you buy the pegboard. We cut it to 60″ by 40″.

Then, I cut the foam to size with my electric meat carving knife – but you could do this with a paring knife or even a bread knife. Since the largest size single piece of 2″ foam sold at JoAnn’s is 24″ by 7.5,’ I worked with that and cut it according to the diagram below. The foam doesn’t actually cover the entire pegboard, but that’s OK because since I wanted the headboard to be able to rest on my box spring, not all of it will show above the mattress.

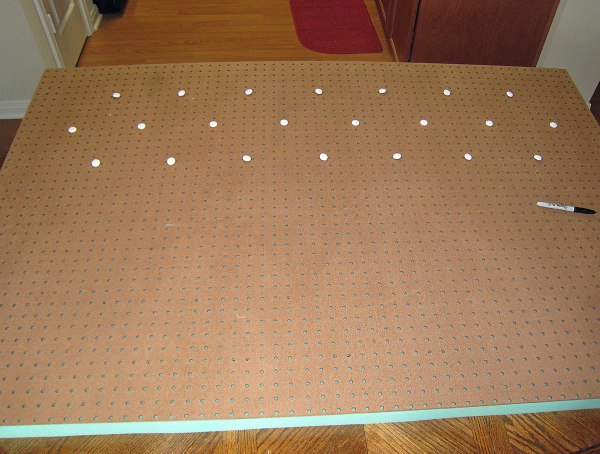

Next, I laid the pegboard on top of the arranged foam pieces and decided where I wanted my tufts. Because I went with the pegboard, I had to work around the spacing already provided. Vertical spacing was pretty flexible because I didn’t care where the bottom row ended up as it would be below the mattress (the headboard is resting on the box spring). Horizontal spacing, on the other hand, had to fit just right to fit on the pegboard with proportional equal borders on both sides. It turned out that 7″ spacing fit evenly with 5″ on each side for the border. Since 7 is odd, though, that meant in every other row the buttons needed to be between two holes – this worked out fine though.

Once I decided where I wanted my tufts, I used a sharpie to mark through the desired holes onto the foam (marking the holes on either side of buttons I wanted to rest between two pegboard holes),

and rearranged the foam back on top of the pegboard.

Next, I cut through the foam with a paring knife to leave holes roughly the diameter of the buttons. This is really important both for getting nice, deep tufts and to make passing the needle in and out through all the layers while finding the right holes in the pegboard much easier. These don’t have to be pretty – the batting will cover up any imperfections. You want to cut the holes all the way through. I first went over all the holes and cut down on top of the pegboard in a circle and just pulled out a chunk of foam. I found that it really helped to hold up the chunk of foam you’re cutting out as you go around once you’ve cut part of the circle to keep it from just being all pushed down by the paring knife, if that makes sense. Then I went back and cut through the last bits while holding up the foam so I could have clear holes all the way through – this helped when lining up the foam on top of the pegboard and when trying to get the needle through and back for the tufts. It also turned out that some of my tuft holes were right on the seam between two pieces of foam – which also worked out just fine and was covered by the batting (so don’t worry if that happens to you!) Then go outside and use some spray adhesive to attach the foam to the pegboard – but make sure the edges and holes for the foam and pegboard line up!

Well, that covers everything prior to adding on the batting and fabric and starting tufting!

Check out part 2 here!

This looks fantastic! And I love the crisp white against that awesome blue wall!

Thanks! The wall is really a navy color – its really hard to photograph!

Hi Julia – what color is it? I have been trying to find the perfect navy, and I really like this one!

Hi. How do you clean a thing like that?

Carefully? haha. Seriously, I don’t see ours getting especially dirty. You could google search something like ‘how to clean upholstered furniture’ (which is basically what this is), but here’s a site that has some good info. http://howto.yellow.co.nz/home-garden/housekeeping-cleaning/how-to-clean-fabric-upholstery/

You could also use a fabric like oil cloth or vinyl – which would clean really easily with just a damp cloth!

This looks so much simpler than I thought it would have been. Can’t wait for part 2! Now following!

Visiting from Whimsically Homemade!

Awesome tutorial – I have been considering making something similar for a while now…

Also, just wanted you to know that I tagged you in a blog post today.

~Amy @ Permanent Kisses

I made an upholstered headboard that I’ve been trying to decide whether or not I want to put the tufting in it. Yours looks great!

I love upholstered headboards too 🙂 One thing to think about though – I think a huge reason my tufts look nice and deep are the holes I cut in the foam before upholstering it. Just realized that it would be really tough to get the same look if you’ve already upholstered it over normal foam. I’d love to see yours!

Wow That is amazing. You did such a wonderful job! I’m impressed!

Thanks for the tutorial.

Rose @

how do you hang it on the wall?

I used hangman metal french cleats (two sets – each rated for 200 lbs). Very easy to install and easy to slide headboard left and right to center.

Nice tutorial!

This is beautiful!

You did an awesome job!! Thanks for the shout out to Pretty Dubs! 🙂

Hi! Really looking forward to getting this project together.

Julia, would you recommend this foam as an alternative to the JoAnn’s (pricey) selection?

Just getting into DIY, still new to this arena…. would appreciate help from a seasoned expert 🙂

鞄 通販 メンズ 鞄 http://www.bagsoratio.info/

Thank you do much for taking the time to share the details of this project. I just finished my headboard today using your instructions. It turned out beautifully!